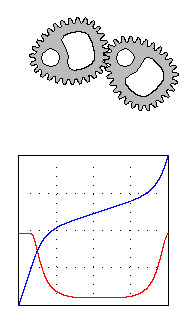

It also lends itself to using a rack-shaped cutter, (see Fig. This method has proved successful, although master gear and pinion are usually preferred for production. To insure correct rolling action during the cutting, steel tapes are wound around the cam and follower, and the diameter of each is made small enough to allow for thickness of the tape. The master noncircular gear can be generated on the same fixture, using a cam and follower in place of the noncircular gear and pinion. The master pinion is a duplicate of the cutter. This method allows using a standard machine with a special work-holding fixture. The gear shaper can also a'ct as a copying machine by having a master gear and pinion regulate the velocity ratio and center distance of the cutter and work. Cutter is held in an eccentric adapter or bushing to vary the linear velocity. 6, to control the center distance of cutter and work spindles. The method is especially suitable for making masters for the production gears.Īnother way is to mount a special cam on a gear shaper, as illustrated in Fig. Norden Laboratory Division of Norden-Ketay, and a few others are also using this technique. He has made the gears illustrated on p 158. Such a unit, coupled to a Fellows gear shaper, has been developed and used by Frederick Cunningham, Stamford, Conn. The tape delivers its instructions to the machine through a special control unit. The center distance between cutter and work, and the angular velocity of the work spindle, is varied in accordance with the instructions contained on a previously prepared tape, which can be paper, plastic, film or magnetic. Perhaps the most accurate way of cutting noncircular gears is the tape-controlled gear shaper.

This involves danger of considerable error at the junction of two segments. Each segment is then cut separately on a gear shaper, so set up that the work rotates about the instantaneous center of the segment.

Simplest method-but also slowest and most expensive -of making noncircular gears involves the division of the gear into several segments, each of which can be considered as approximating an arc of a circle.

I've had good success with regular gears in wooden clocks, etc.ĬhrisDo not know if your local library can get a copy of this: My interest is primarily for for visual effect in dynamic wood sculpture. I am looking for CAD drawings, or software for creating, or a clear theoretical description for designing/cutting non-circular gears.

0 kommentar(er)

0 kommentar(er)